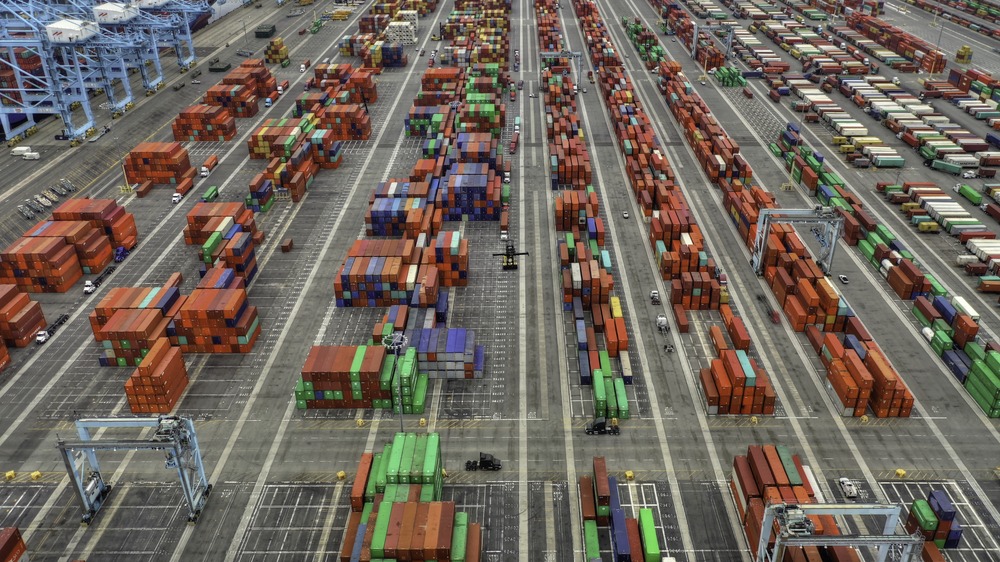

Peak shipping season puts intense pressure on ports, terminals, and transportation networks across New York City. Even with a trusted drayage provider in place, delays, detention fees, and poor coordination can disrupt delivery schedules and hurt bottom lines. Proactive planning is key, especially when it comes to aligning warehouse capacity, timing container pickups, and staying ahead of congestion.

Here are five practical tips to help businesses get the most out of their drayage trucking service during peak season.

Table of Contents

Key Takeaways

✔ Book container pickups early to avoid missed appointments and reduce peak-season delays.

✔ Coordinate with warehouses in advance to ensure dock space and smooth unloading.

✔ Use pre-pull services to move containers off terminal before congestion builds.

✔ Diversify terminals and rail options to bypass bottlenecks and spread out volume.

✔ Stay in constant contact with drayage partners to adapt quickly to sudden changes.

✔ Manage empty container returns early to avoid per diem fees and scheduling issues.

✔ Monitor terminal alerts closely and adjust drayage plans in real time.

1. Schedule Container Pickups Early

The earlier businesses lock in container pickups, the better they can avoid costly delays. Terminals in New York City operate on strict appointment windows during peak season, and slots fill up fast. Timely scheduling supports better planning across port drayage trucking in NYC.

How Early Scheduling Reduces Disruptions

- Avoid Last-Minute Terminal Congestion: When appointments are booked too close to deadlines, drivers face longer wait times and may miss gate cutoff times. Early scheduling allows drayage providers to plan routes more efficiently and avoid congested periods at terminals.

- Secure Preferred Pickup Times: Not all pickup windows are created equal—some time slots are faster and more reliable than others. Booking early gives businesses access to these high-performing windows, improving the performance of terminal drayage trucking in NYC.

- Reduce Demurrage and Detention Fees: Containers sitting at the port too long can rack up daily fees. By scheduling pickups ahead of time, businesses give their partners for rail drayage trucking in New York City enough lead time to pull freight before those costs begin to build.

2. Coordinate Closely With Warehouses

Peak season creates a ripple effect—when one part of the chain slows, everything else backs up. Even if port drayage trucking in NYC runs smoothly, delays at the warehouse can cause missed returns, detention fees, and storage bottlenecks. Good communication keeps goods flowing and prevents costly missteps.

How to Ensure Warehouse Readiness During Peak Season

- Prepare Dock Schedules for Inbound Containers: When warehouses don’t know exactly when freight is arriving, unloading delays can snowball. A tight connection between warehouse staff and the port-to-warehouse drayage in NYC ensures docks are ready when containers show up.

- Clear Floor Space in Advance: Full floors and limited racking slow down receiving and inventory processing. Make space early so containers moved by ocean container drayage in NYC can be unloaded and turned around quickly.

- Align Receiving Hours With Drayage Deliveries: Not every warehouse accepts freight at all hours, especially on weekends. Coordinating delivery hours with terminal drayage trucking in NYC reduces the risk of redelivery charges and delays.

3. Use Pre-Pull and Storage Services

Chassis shortages and terminal backlogs are common during high-volume months. Pre-pulling containers—removing them from the terminal and storing them off-site—gives businesses more control over timing.

How Pre-Pull Services Improve Delivery Flexibility

- Reduce Time Pressure at Terminals: When a drayage provider pre-pulls a container, it’s moved out of the terminal and into a secure yard before the delivery date. This gives businesses using port drayage trucking in NYC a cushion against unexpected gate closures or appointment delays.

- Avoid Costly Detention and Per Diem Fees: Pre-pulled containers don’t sit idle while warehouse teams scramble to unload. With better timing between port-to-warehouse drayage in NYC and warehouse readiness, businesses avoid extra charges.

- Stabilize Delivery Schedules During Spikes: When the terminal gets overloaded, scheduled appointments might be pushed or canceled. Pre-pulling provides flexibility, allowing rail drayage trucking in New York City to maintain service consistency during disruptions.

4. Diversify Port and Rail Options

Relying on a single terminal or rail yard during peak season is risky. Weather delays, labor slowdowns, or heavy container volumes can overwhelm one location while others stay manageable. Exploring alternatives opens new routes and reduces dependency on bottlenecked sites.

How to Use Alternative Routes to Keep Freight Moving

- Use Multiple Terminals Strategically: Not every terminal operates with the same efficiency or congestion levels. Businesses that diversify their terminal drayage trucking in NYC partners can route containers through less congested facilities for faster turnaround.

- Tap Into Nearby Rail Yards: Intermodal solutions like port-to-rail drayage in New York City offer an alternative to crowded highways and container yards. Using nearby rail ramps can ease pressure off the port and shift volume inland faster.

- Split Volume Across Carriers and Routes: Don’t overload one system while another remains underutilized. When ocean container drayage in NYC is stretched thin, mixing in rail drayage trucking in New York City helps balance the load and protect delivery timelines.

5. Communicate Constantly With Drayage Partners

Even with the best planning, things change fast during peak season. Ports close gates early, appointments shift, and weather causes unexpected shutdowns. Open communication with drayage providers keeps everyone aligned and ready to adapt.

How to Ensure Consistent Communication With Partners

- Stay Updated on Port Conditions: Drayage carriers have firsthand knowledge of terminal delays, backlogs, and chassis availability. Businesses using port drayage trucking in NYC can adjust faster when they’re in constant contact with drivers and dispatch teams.

- Reschedule Quickly When Needed: Delays happen, but the faster they’re addressed, the smaller the impact. Having direct lines to port-to-warehouse drayage in NYC allows for quicker rescheduling and better resource use.

- Align Expectations on Delivery Priorities: Not every shipment is equal—some need to move now, others can wait. When businesses communicate shipment urgency clearly, partners for ocean container drayage and rail drayage trucking in New York City can prioritize the right loads.

How to Manage Return Logistics and Empty Container Planning During Peak Season

Empty container returns often get overlooked during peak shipping season. However, poor planning here can lead to serious delays and extra costs. With limited return windows, strict terminal cutoffs, and chassis shortages, businesses need a clear return strategy.

The right approach not only saves time and money but also supports smoother coordination with port drayage trucking in NYC and beyond. This is especially crucial now, even if container shipping remains the most cost-effective way to move cargo since the 1950s.

1. Schedule Empty Returns as Soon as Containers Are Unloaded

Don’t wait to plan empty container returns after unloading—coordinate the return schedule while the container is still en route. Many terminals in New York City require advance notice for returns, especially during peak congestion. Drayage providers handling terminal drayage trucking in NYC can reserve return slots ahead of time to avoid missed windows.

2. Use Drayage Partners With Yard Storage Capabilities

Some businesses struggle to return containers immediately due to tight warehouse unloading times or limited terminal hours. Partnering with carriers of port-to-warehouse drayage in NYC that offer off-site yard storage helps bridge that gap. Containers can be pre-pulled and held temporarily until return windows open, avoiding detention fees.

3. Communicate With Ocean Carriers on Return Locations

Ocean carriers often assign specific return depots for empty containers, which can change during peak periods. If this info isn’t updated quickly, containers may be returned to the wrong facility—resulting in rejections or fines. Businesses should stay in regular contact with carriers and share updated return instructions with their providers of ocean container drayage in NYC.

4. Track Chassis Availability for Return Timing

Empty containers can’t move without chassis, and shortages are common during peak season. Coordinating closely with port drayage trucking companies ensures chassis availability aligns with return schedules. Having visibility into chassis pool access through the drayage partner reduces idle time and return disruptions.

5. Use a Staggered Return Approach for High-Volume Freight

Returning multiple containers at once can overwhelm receiving terminals and delay acceptance. A staggered return schedule allows businesses to break down return volumes and space out delivery to terminal yards. This tactic supports both terminal drayage trucking and rail drayage trucking in New York City operations by easing congestion at drop-off points

6. Confirm Empty Return Deadlines to Avoid Per Diem Charges

Ocean carriers set strict per diem deadlines—every extra day costs money. Businesses must document delivery times and return cutoffs clearly to avoid disputes and late fees. Working with experienced providers of port-to-rail drayage in New York City helps ensure containers are returned on time, even when juggling multiple destination points.

How to Monitor and Respond to Terminal Alerts Efficiently

During peak season, terminal conditions in New York City can shift fast—gates close early, chassis availability changes, and appointment windows vanish in hours. Terminal alerts help businesses stay updated, but reacting too slowly can lead to delays, extra fees, or missed pickups.

Knowing how to read and act on these updates ensures smoother coordination across services like port drayage trucking in NYC.

1. Sign Up for Terminal Alert Subscriptions From Multiple Ports

Each terminal in NYC operates independently and issues its own updates via email, SMS, or web notifications. Businesses should subscribe to all terminals they use to avoid missing sudden closures or appointment changes. This gives dispatch teams time to adjust schedules proactively.

2. Verify Gate Statuses Before Dispatching Trucks

Some terminals close early without notice, especially during high-volume periods. Before sending out trucks for pickup or return, businesses should confirm real-time gate statuses through the terminal’s official platform or via the drayage provider. This helps avoid wasted trips and supports better planning for ocean container drayage in NYC.

3. Cross-Check Alerts With Chassis Pool Availability

Even if a terminal is open, limited chassis supply can delay pickup and return times. Businesses should cross-reference alerts with chassis availability systems or consult their port drayage trucking partner. Staying ahead of this information reduces downtime and minimizes detention risks.

4. Communicate Alert Changes Immediately to Drayage Partners

When alerts indicate new cutoff times, yard closures, or restricted access, delays are inevitable unless the drayage provider knows right away. A quick call or dispatch message to the terminal drayage trucking in NYC ensures route and timing changes are handled swiftly. This level of communication prevents scheduling conflicts and late penalties.

5. Use TMS Platforms That Integrate Live Terminal Feeds

Transportation management systems (TMS) that display real-time terminal data give businesses a clear edge during peak season. These systems help flag gate closures or access restrictions automatically, allowing companies to reroute containers moved via rail drayage trucking in New York City without delay. Investing in the right tools cuts manual tracking time and improves response speed.

6. Review Historical Alert Trends to Predict Problem Periods

Past terminal alerts can help identify patterns—such as consistent Friday congestion or delayed Monday openings. Businesses can use this insight to plan future appointments, especially for high-volume periods requiring multiple moves with port-to-rail drayage in New York City. Learning from these trends helps build more resilient, flexible delivery schedules.

Understanding the Differences Between Port, Terminal, and Rail Drayage Services

Drayage isn’t one-size-fits-all—different service types serve different parts of the container journey. Knowing how port drayage, terminal drayage, and rail drayage operate helps businesses plan more efficiently and reduce risks during peak season.

Each one plays a specific role in moving containers across the supply chain in and around New York City, and with the drayage market projected to reach $73.45 billion by 2029, understanding these distinctions has never been more important.

1. Port Drayage: The First Step Off the Vessel

Port drayage trucking in NYC handles the initial move of containers from the port to the next point in the supply chain. This may involve transporting containers to a nearby warehouse, yard, or rail hub for further handling. It’s the most time-sensitive phase and often faces delays from terminal congestion and chassis shortages.

2. Terminal Drayage: Moving Containers Within the Port Complex

Terminal drayage trucking in NYC involves short hauls between container terminals or from one part of a port complex to another. It’s often used to reposition containers for inspections, consolidations, or transfers to a different shipping line. While these moves are short in distance, they require strong coordination to prevent bottlenecks inside the port.

3. Rail Drayage: Connecting Port Cargo to Inland Rail Yards

Rail drayage trucking in New York City moves containers between seaports and rail ramps, supporting long-haul inland transport. It plays a key role in intermodal shipping, especially when containers are heading to distribution centers outside the NYC metro area. Timing and scheduling are critical to avoid missing train cutoffs or delaying transits.

4. Port-to-Rail Drayage: Coordinating Seamless Intermodal Transfers

Port-to-rail drayage in New York City refers to the direct connection between marine terminals and rail yards. These moves require tight planning to ensure containers are ready for rail loading without sitting idle. This service helps reduce highway congestion and supports faster inland delivery during peak season.

5. Port-to-Warehouse Drayage: Serving Final Mile Distribution Needs

Port-to-warehouse drayage in NYC focuses on moving cargo from the port directly to the importer’s or retailer’s storage facility. This is common for businesses distributing goods locally or regionally. It requires flexibility and strong coordination with warehouse teams to avoid unloading delays and return issues.

6. Ocean Container Drayage: Covering All Port-Based Container Moves

Ocean container drayage in NYC is a broader category that includes all container moves related to marine shipments, whether to a rail yard, warehouse, or storage yard. It requires drayage providers to manage container appointments, documentation, and compliance with steamship line protocols. These moves are time-sensitive and often the most affected by terminal congestion and port volume spikes.

Frequently Asked Questions (FAQs)

What documents are required for a smooth drayage pickup in NYC?

To ensure smooth port drayage trucking in NYC, businesses must provide accurate delivery orders, container release information, and any necessary customs clearance documentation. Without these, carriers may be turned away at the terminal gate, causing costly delays. Partnering with a drayage company that understands documentation workflows for ocean container drayage in NYC can prevent issues at pickup.

Can drayage services handle overweight containers?

Yes, but overweight loads must comply with specific NYC and DOT regulations regarding axle weight and total gross weight. Not all providers of port drayage trucking in NYC are equipped for heavy haul permits or specialized chassis. It’s best to confirm weight limits and capabilities early, especially for terminal drayage trucking in NYC during peak periods.

How does weather impact drayage service schedules?

Severe weather can lead to port closures, reduced gate hours, and restricted access to terminals and rail ramps. Rail drayage trucking in New York City may also experience service slowdowns due to slippery roads or yard flooding. Planning ahead and staying in contact with port-to-rail drayage partners helps minimize disruptions.

What happens if a container is held for inspection?

If U.S. Customs or another agency flags a container, it may be delayed at the terminal for examination. This can impact delivery schedules and require rescheduling with terminal drayage trucking in NYC. Businesses should notify their carrier of port-to-warehouse drayage in NYC immediately to prevent missed appointments or detention fees.

Are drayage services available 24/7 during peak season?

Not all drayage carriers operate around the clock—availability depends on driver schedules, terminal hours, and warehouse receiving times. Some providers of port drayage trucking in NYC offer extended hours during peak shipping season, but coverage varies. For flexibility, it’s smart to coordinate with companies that offer late pickups or weekend service.

Streamline Peak Season with Drayage Company By Best

Keep containers moving without the chaos—Drayage Company By Best delivers fast, reliable service across New York City’s busiest ports and rail terminals. Whether it’s port-to-rail drayage or direct port-to-warehouse drayage, our team handles the pressure so businesses don’t have to. With deep local expertise, flexible scheduling, and a commitment to beating congestion, we’re the partner shippers trust when time matters most.

Don’t let peak season slow things down—move smarter with Drayage Company By Best!