Port congestion, supply chain disruptions, and labor shortages have dominated logistics headlines—but a less visible factor often sits at the root of many delays: chassis shortages. These wheeled frames are essential for moving shipping containers between ports, rail yards, and warehouses, yet many businesses underestimate their role until shipments are stuck in limbo. As companies scramble to meet delivery expectations, the connection between limited chassis availability and drayage delays becomes increasingly clear.

Here are five ways the connection between chassis shortages and delays is reshaping how businesses evaluate and rely on drayage services for containers.

Table of Contents

Key Takeaways✔ Chassis shortages are a major but often overlooked cause of drayage delays. ✔ Understanding what is container drayage helps businesses avoid costly supply chain issues. ✔ Drayage delays can lead to detention fees, lost sales, and warehouse inefficiencies. ✔ Choosing the right container drayage trucking provider reduces risk during chassis shortages. ✔ Integrating drayage planning into your supply chain strategy improves timing and cost control. ✔ Real-time visibility and proactive communication are critical for successful drayage transportation for containers. ✔ Businesses that grasp the full container drayage meaning make smarter, more resilient logistics decisions. |

What Is Container Drayage?

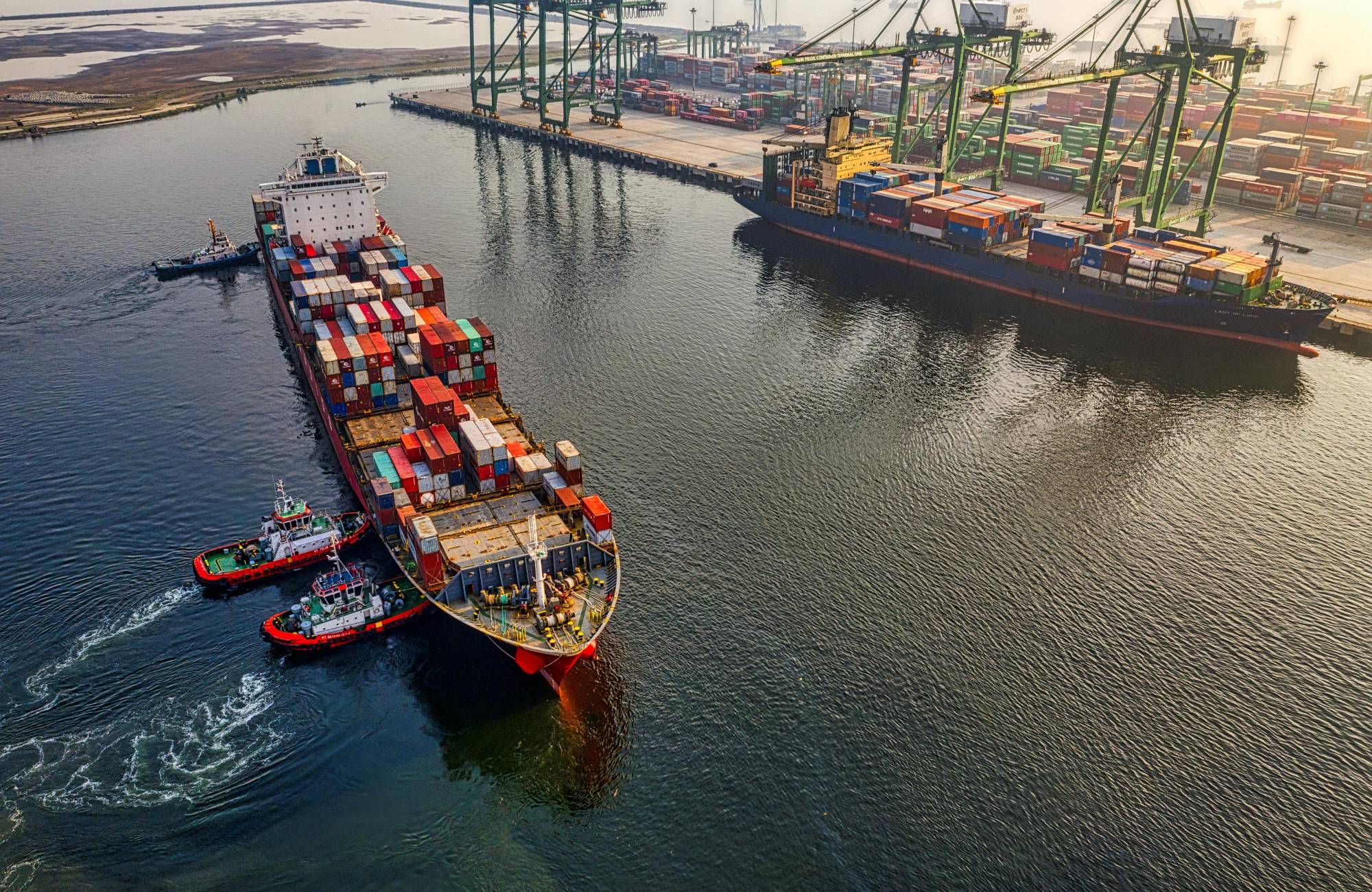

Container drayage is a short-distance transportation service that moves shipping containers between ports, rail yards, and local warehouses or distribution centers. For businesses, understanding the definition of container drayage is key to managing the crucial first or last leg of their freight’s journey.

The full meaning goes beyond simply moving cargo—it involves time-sensitive coordination that directly affects inventory flow and delivery timelines. As the e-commerce industry continues to grow, demand for efficient drayage services is expected to rise in response.

For companies evaluating logistics options, knowing “what is container drayage?” helps in choosing partners that can streamline operations and reduce costly delays.

5 Ways Chassis Shortages Are Reshaping Drayage Services for Containers

1. Longer Turnaround Times for Each Container

Chassis shortages slow down every step of the drayage process, from pickup at the port to final delivery. When drivers can’t find available chassis, containers sit idle—clogging up space and disrupting schedules. Businesses relying on drayage transportation for containers face unexpected delays that ripple through inventory and production timelines.

How Chassis Shortages Increase Container Dwell Time

- Fewer Chassis at Terminals: Without enough chassis on hand, containers cannot leave the port—even if drivers and trucks are ready. This bottleneck extends container dwell times and creates costly delays for businesses that need quick turnaround.

- Backlogs at Return Locations: Returning empty containers is just as important as picking up loaded ones, but chassis scarcity limits how quickly empties can be moved. This creates return backlogs that block new shipments from being released.

- Driver Time Wasted on Waiting: Drayage drivers spend hours waiting for chassis to become available, cutting into how many runs they can complete in a shift. This reduces the efficiency of container drayage trucking and adds to operational costs.

2. Higher Drayage Costs for Businesses

As chassis availability drops, operating costs for drayage providers rise—and those costs get passed down to businesses. Companies looking for reliable drayage services for containers may find rates creeping up even when distance and cargo volume remain unchanged. These rising expenses are often tied to inefficiencies created by the shortage.

How Chassis Shortages Drive Up Costs

- Increased Rental and Pool Fees: When providers don’t have their own chassis, they must rent from chassis pools or third-party owners. These rentals come with premium fees that push up the cost of container drayage trucking.

- More Idle Time per Load: Drivers lose time searching for available chassis, waiting in long lines, or handling container returns. That lost time reduces daily productivity, leading to higher labor costs per trip.

- Additional Fuel and Route Adjustments: Chassis shortages sometimes require rerouting to terminals with better availability, even if they’re farther away. These detours add fuel costs and increase the total expense of drayage transportation for containers.

3. Strained Carrier Relationships and Scheduling Gaps

Chassis shortages don’t just delay containers—they disrupt carefully coordinated partnerships. When schedules break down, it becomes harder for businesses to rely on consistent pickup and delivery windows. Companies that don’t understand the definition of container drayage may underestimate how fragile these timelines can be.

Causes of Scheduling Gaps

- Missed Appointments at Ports and Yards: If a chassis isn’t available on time, a truck can miss its appointment slot—sometimes delaying a shipment by hours or days. These missed slots create costly rescheduling issues and frustrate both shippers and carriers.

- Reduced Flexibility with Drivers: Drayage providers often work within tight timeframes, especially near ports. When chassis are limited, businesses face less flexibility and must work around narrow availability windows for container drayage trucking.

- Breakdowns in Communication: Rapid changes in equipment availability require constant updates. Businesses without strong communication channels with their drayage transportation for containers provider may struggle to adjust in real time.

4. Bottlenecks in Warehouse Operations

When containers are delayed at the port, warehouses feel the ripple effect. Products arrive later than expected or pile up all at once, throwing off staffing, storage planning, and inventory flow. These slowdowns highlight how chassis shortages impact more than just transportation—they create operational challenges upstream.

Why Warehouses Get Overwhelmed

- Uneven Delivery Patterns: Without steady chassis access, containers may arrive in clusters after days of delay. This floods warehouses with goods that all need to be processed at once, stretching labor and space.

- Inventory Gaps and Stockouts: Delayed drayage services for containers mean inventory doesn’t arrive when needed. This disrupts order fulfillment, especially for businesses that depend on just-in-time inventory systems.

- Overuse of Temporary Storage: To make room for delayed containers, some businesses turn to overflow storage or yard space. These workarounds often come with added costs and logistical challenges, especially if they’re unplanned.

5. Increased Risk of Missed Delivery Deadlines

Every link in the supply chain depends on timing—and when containers get stuck waiting for chassis, deadlines slip. From retail product launches to manufacturing production schedules, the stakes are high. Businesses that don’t grasp what is container drayage may miss how critical this service is to meeting delivery goals.

How Delays Lead to Missed Commitments

- Disrupted Production Schedules: Manufacturers waiting on parts or raw materials can’t meet output goals if containers are delayed. This slows operations and may result in missed delivery contracts or penalties.

- Retail and Seasonal Timing Risks: For retailers, especially during peak seasons, container delays can mean empty shelves or missed promotional windows. That missed opportunity impacts revenue and customer trust.

- Compromised Customer Commitments: Businesses making B2B deliveries risk harming client relationships when goods arrive late. Choosing container drayage trucking providers that actively manage chassis constraints becomes a strategic priority.

How to Choose the Right Container Drayage Trucking Provider During a Chassis Shortage

Choosing the right drayage partner in New York City can make the difference between smooth operations and costly delays—especially when chassis are in short supply. Businesses that understand what container drayage is and how it fits into the broader supply chain are better equipped to make informed decisions.

The right provider not only moves containers but also helps navigate real-time challenges, including equipment shortages and cost considerations, including the average shipping container rental rate of $125 per month.

1. Look for Providers with Owned or Priority Access to Chassis

Drayage companies that own their own chassis or hold priority access in chassis pools are better equipped to keep freight moving when shortages hit. These providers don’t rely solely on first-come, first-served availability, reducing risk of idle containers. Businesses that understand the definition of container drayage will recognize this as a strategic advantage, especially during peak congestion.

2. Evaluate Their Port and Terminal Relationships

Experienced drayage providers often build strong working relationships with terminal operators, which can speed up container release and pickup times. These connections help reduce bottlenecks when drayage services for containers are in high demand. A provider with strong ties can help businesses move freight even when chassis are tight.

3. Ask About Real-Time Tracking and Communication Tools

In a shortage scenario, visibility matters. Providers offering real-time tracking for both container status and chassis availability allow businesses to plan ahead and respond faster. For companies still learning what is container drayage, this visibility builds trust and simplifies day-to-day logistics.

4. Confirm Experience with Volume and Complexity

Not all container drayage trucking providers can handle large or time-sensitive shipments under pressure. Businesses should ask for references, case studies, or examples of past performance during peak seasons or disruptions. Providers with proven experience are more likely to manage complex drayage transportation for containers without falling behind.

5. Review Flexibility and Contingency Planning

Chassis shortages often require quick decisions—rerouting, rescheduling, or even storage adjustments. A good provider will have contingency plans and the flexibility to adjust in real time without compromising delivery commitments. This adaptability shows a deeper understanding of the full container drayage meaning beyond just moving freight.

6. Prioritize Providers Who Understand Business Objectives

Drayage shouldn’t be treated as a one-size-fits-all service. Professional providers take time to learn a client’s goals, supply chain flow, and critical deadlines, customizing their approach accordingly. When a company knows the true value of container drayage trucking, it becomes easier to spot partners who are invested in long-term success—not just one-off moves.

How to Integrate Drayage Planning Into Supply Chain Strategy

Many businesses treat drayage as an afterthought—just a quick move from the port to a warehouse. But when chassis shortages strike, that mindset can lead to delays, higher costs, and supply chain breakdowns. Integrating drayage services for containers into broader logistics planning helps companies stay agile and competitive, especially when understanding the full definition of container drayage becomes vital.

1. Align Drayage Schedules with Inventory Flow

Drayage transportation for containers should be timed with warehouse receiving schedules to avoid congestion and downtime. When planning inbound freight, businesses should coordinate arrival windows based on actual unloading capacity. This prevents overflow and ensures what is container drayage fits smoothly into distribution operations.

2. Build Buffer Time Around Port Operations

Ports are unpredictable—labor strikes, weather, and chassis availability can all throw off tight schedules. Businesses that factor in buffer time when scheduling container drayage trucking reduce the risk of costly ripple effects. Professional drayage partners can help estimate realistic timelines based on current port conditions.

3. Incorporate Drayage into Freight Procurement Strategy

Instead of booking drayage separately from ocean or rail freight, businesses can gain efficiency by bundling these services with a provider who understands the full container drayage meaning. This integrated approach supports smoother coordination and fewer handoffs. It also ensures chassis planning is considered upfront, not as a last-minute scramble.

4. Use Demand Forecasting to Predict Drayage Needs

Forecasting tools that anticipate container arrivals and shipment volumes allow businesses to plan chassis needs early. This data-driven approach improves availability and helps avoid the pitfalls of underestimating drayage services for containers. Partnering with providers who align with these forecasts ensures better execution.

5. Leverage Professional Insights During Seasonal Peaks

Peak shipping seasons strain the system, especially when chassis are already limited. Businesses that rely on experienced container drayage trucking providers can benefit from historical knowledge and early preparation strategies. These professionals often know how to navigate congestion and secure equipment before demand spikes.

6. Establish KPIs Specific to Drayage Performance

Too often, companies measure delivery success without isolating drayage as a performance factor. Creating KPIs around pickup times, dwell durations, and missed appointments helps identify gaps early. A business that understands the definition of container drayage will see the value in tracking these metrics to improve supply chain reliability.

Understanding the Real Cost of Drayage Delays for Businesses

Drayage delays do more than disrupt shipping schedules—they directly affect a company’s bottom line. When businesses fail to factor in the hidden costs tied to chassis shortages and port congestion, they risk margin erosion, customer dissatisfaction, and operational setbacks. By understanding what is container drayage and how delays impact multiple areas, decision-makers can take smarter, more cost-conscious steps forward.

1. Rising Detention and Demurrage Fees

When containers sit too long at a terminal or with a carrier due to unavailable chassis, detention and demurrage charges stack up quickly. These fees can climb into thousands of dollars per container depending on the delay. Companies that know the definition of container drayage can better plan for pickup windows and avoid unnecessary charges.

2. Missed Sales and Lost Revenue

Retailers and manufacturers waiting on delayed goods often miss critical sales opportunities, especially during promotional cycles or peak seasons. When drayage services for containers break down, shelves stay empty or production stalls—costing real revenue. These losses are hard to recover and emphasize why container drayage trucking must be tightly managed.

3. Increased Labor and Overtime Costs

When shipments arrive late or all at once, warehouse staff are forced to work overtime to catch up. Businesses end up paying more to process containers that could have been handled smoothly with better drayage transportation for containers. Labor unpredictability leads to staffing inefficiencies and budget overruns.

4. Disrupted Production and Fulfillment Schedules

Manufacturing facilities waiting on raw materials or parts from delayed containers often must halt or slow down production. This affects output, customer delivery timelines, and overall efficiency. Understanding the container drayage meaning in the context of production flow helps businesses avoid cascading impacts.

5. Higher Administrative and Planning Overhead

When delays happen, logistics teams scramble to reschedule appointments, rebook carriers, and track down missing containers. This extra coordination eats into productivity and inflates administrative labor costs. Working with experienced professionals who understand what is container drayage reduces this last-minute chaos.

6. Damage to Customer Relationships and Brand Reputation

Late deliveries can erode trust, especially in B2B relationships where clients depend on strict timelines. Businesses that repeatedly experience unreliable container drayage trucking may see partners turn to competitors. Protecting service quality starts with recognizing the financial and reputational cost of delayed drayage services for containers.

Frequently Asked Questions (FAQs)

Drayage services for containers typically handle 20-foot, 40-foot, and sometimes 45-foot intermodal shipping containers. These containers may be loaded with raw materials, finished goods, or temperature-sensitive freight. Regardless of size or cargo, reliable container drayage trucking ensures that containers move efficiently between ports, rail ramps, and final destinations.

Yes, most professional drayage providers handle both import and export container moves. Whether it’s bringing inbound freight from a port or moving an export load to a terminal, understanding what is container drayage helps businesses ensure both legs of the journey are covered. Planning both directions reduces delays and balances chassis usage.

No, container drayage is also used at inland rail terminals, cross-dock facilities, and intermodal hubs—not just coastal ports. The definition of container drayage includes any short-distance movement between key logistics points, whether by ocean or rail. Businesses in landlocked regions still rely heavily on drayage transportation for containers.

Drayage focuses on short, time-sensitive moves—often under 100 miles—between ports, rail yards, and warehouses. Unlike long-haul trucking, container drayage trucking involves tight windows and close coordination with terminal schedules. Knowing the container drayage meaning helps businesses distinguish it from broader freight services.

Before drayage transportation for containers can begin, imported containers must be cleared by customs and released by the port. Delays in documentation or clearance can hold up the entire drayage process. Businesses that understand what is container drayage often build customs timing into their logistics strategy to avoid unexpected setbacks.

Streamline Your Freight With Drayage Company By Best

When timing, precision, and experience matter, Drayage Company By Best delivers reliable container drayage trucking across New York City’s busiest ports and terminals. Our team understands the real-world pressures businesses face and provides tailored drayage services for containers that keep your operations running on schedule—even during chassis shortages. From timely pickups to port coordination, we handle the critical first or last mile so you can focus on what moves your business forward.

Reach out today to put the power of seasoned drayage professionals behind your supply chain.